TECHNOLOGICAL PROCESSES

CLEANING

Before we start work on any element, it is thoroughly cleaned.

We use special detergents and pressure water jets to clean elements. Only clean elements may be refurbished. Once cleaned, the elements are sand blasted.

CUTTING

In the refurbishment process, we use elements from your heat exchanger which are intact and in working order.

We are very skilful at this, and use high quality tools. We do this so that you can save on purchases and hear exchange system elements replacement costs.

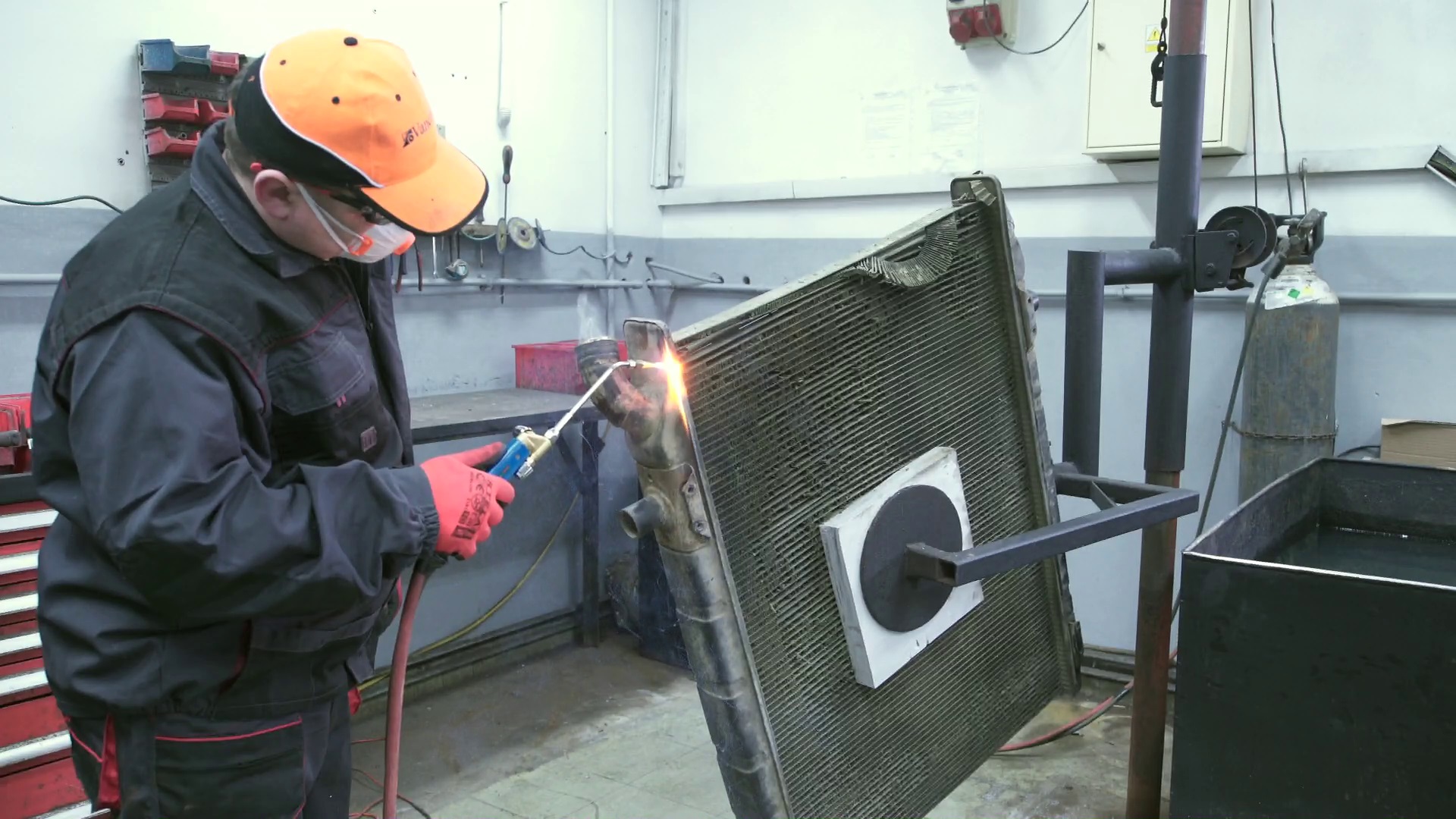

WELDING

Use weld using all methods and all types of materials.

The elements are aligned on a master table and welded by experienced welders.

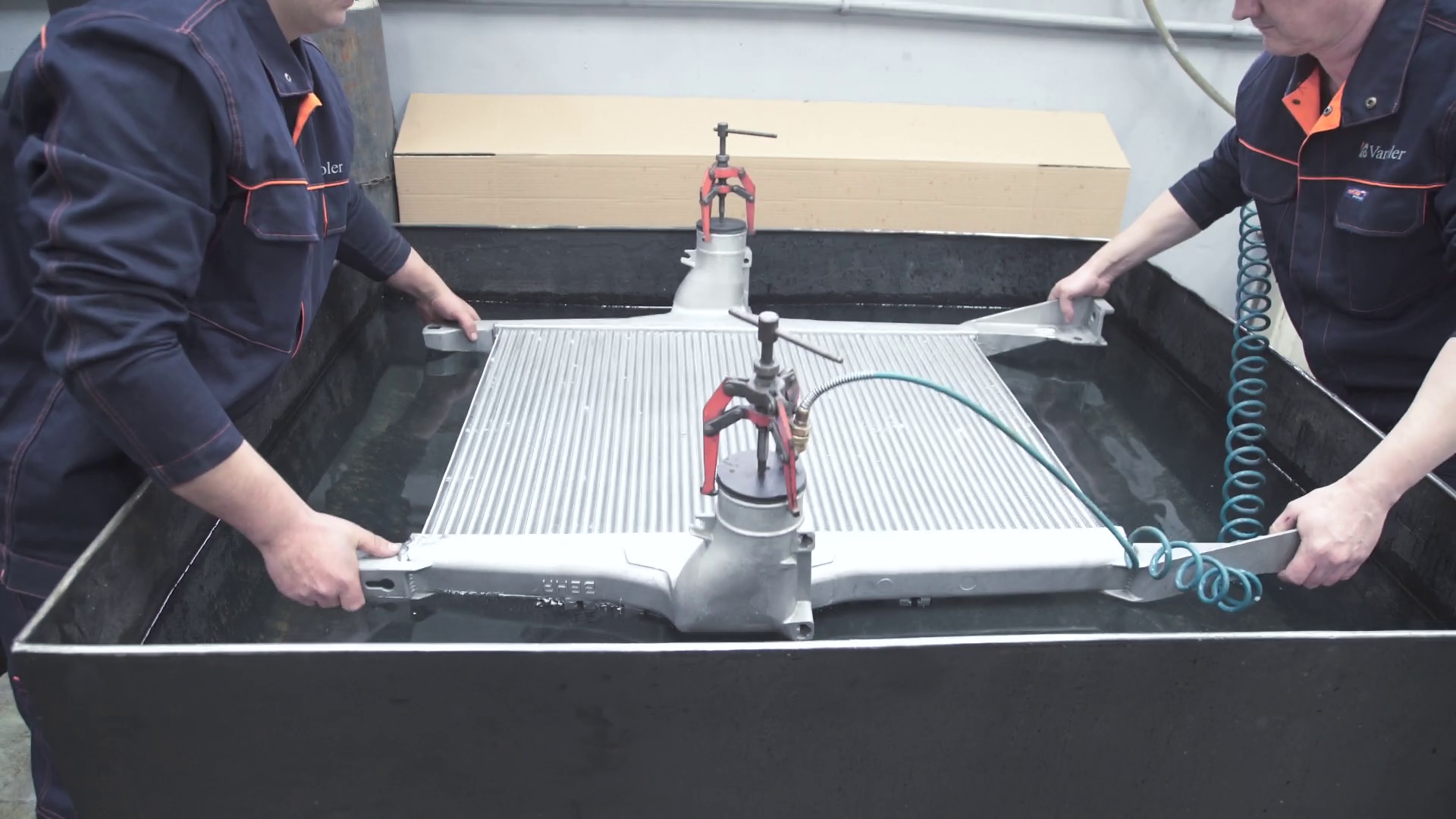

TESTING TIGHTNESS

This first of a number of quality tests. Tightness test. Each radiator, intercooler or recirculator is subjected to a tightness test.

We want to be sure that the products our customers receive are of the highest quality.

OFFICES